What is Factory Automation?

Factory automation is the implementation of technology and systems to automate a manufacturing process with the ultimate goal of increasing productivity and reducing costs. The level of automation may be anything from single operation automations to end-to-end automation where there is no human involvement. Factory automation can be implemented at any point in the manufacturing process from material quantity control, to production and assembly and finally to packaging and dispatch.

This article deals with the basic types of automation, the benefits of factory automation finally the cost considerations.

Types of Factory Automation

The degree of automation will vary depending on the manufacturing process, budget and a range of other criteria. Most industries have some level of automation.

Manual / Minimal Automation

There may be a little automation in this, but on the whole the process is manual. Examples are quality inspection, manual product assembly etc. This relies on training, expertise and human judgement for the process.

Single automated machines

Use of single machines that are designed to automate a single repetitive process like inspection, cutting packaging etc. The parts may be manually inserted and positioned into the equipment.

Automated Production lines

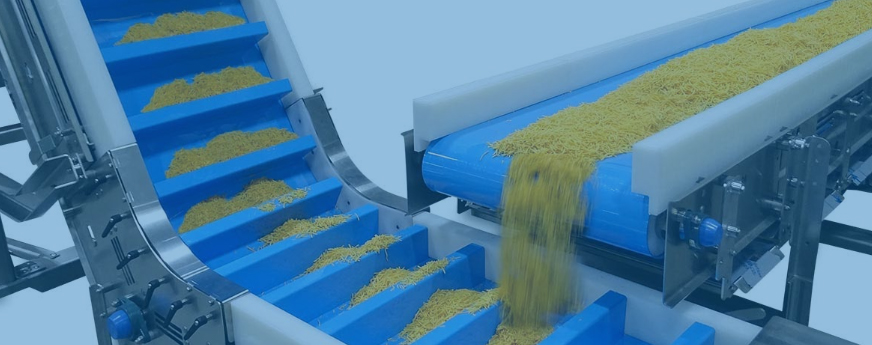

Automated production lines typically combine material transfer on a conveyor system with a series of dedicated workstations each designed to fulfill a particular propose in the productions cycle. The sequence is fully defined and the level of operator involvement depends on the amount of automation. In a fully automated line operators are needed only for supervision, monitoring, adjustment and maintenance of the equipment.

Fully automated (end-to-end)

The ultimate solution is the end-to-end automated factory where there are no operators and the factories can run 24 hours per day 365 days per year. These factories may even include self-adjustment and quality measurement of products.

Benefits of Factory Automation

Improved Productivity

One of the main drivers of factory automation must be improved productivity. The advantages of potential 24/7/365 production and streamlined processes cannot be underestimated.

Improved quality

Repeated tasks that are continually monitored and adjusted and reduced human error.

Improved Consistency

Similar to the improved quality, the repeatability of an automated process makes the results more predictable and reduces any variations that be related to different operators and other human factors.

Reduced Waste

Improved planning with automated production and the improved repeatability leads to reduced waste.

Safer Working Conditions

Automating dangerous processes and built-in shut-down coupled with less operator involvement leads to a safer working environment and considerable risk reduction.

Cost Saving

This is the main driver and is a combination of all the above. Increased productivity, reduced down-time, reduced training costs and elimination of accidents leads to significantly improved profitability after the initial outlay of automating the system.

Cost of Implementation

The initial outlay is usually high and the equipment used to automate a production line is very specialised and often needs to be designed and developed for a particular line.

The design may also be costly as it is important to develop a future-proof design that allows the throughput to increase as successes are realised.

Best practices exist, as do generic solutions. Employing an experienced automation engineer can help to design a system that uses existing technologies where possible to contain the costs.

There also will be the costs of upskilling operators to monitor the process or there will be the cost of sourcing and employing these people to supervise and monitor the production line.